Cellulose fiber

Fibre cellulose (/ ˈsɛljʊloʊs, -loʊz/) bụ eriri ethers ma ọ bụ esters nke cellulose, nke enwere ike nweta site na ogbugbo, osisi ma ọ bụ akwụkwọ osisi, ma ọ bụ site na ihe ọkụkụ ndị ọzọ. Na mgbakwunye na cellulose, eriri nwere ike ịnwe hemicellulose na lignin, yana pasent dị iche iche nke ihe ndị a na-agbanwe ihe eji arụ ọrụ nke eriri.

Ngwa ndị bụ isi nke eriri cellulose dị na ụlọ ọrụ textiles, dị ka ihe nzacha kemịkalụ, yana dị ka ihe mgbagwoju anya na-eme ka eriri, n'ihi ihe ndị yiri ya na eriri ndị emepụtara, bụ nhọrọ ọzọ maka biocomposites na polymer composites.

Akụkọ ihe mere eme

dezieAchọpụtara Cellulose na 1838 site n'aka onye France chemist Anselme Payen, onye kewapụrụ ya na ihe ọkụkụ ma kpebie usoro kemịkal ya. A na-eji cellulose mepụta polymer thermoplastic nke mbụ na-aga nke ọma, celluloid, nke Hyatt Manufacturing Company na 1870. Mmepụta rayon ("silk artificial") sitere na cellulose malitere na 1890, na cellophane mepụtara na 1912. Na 1893, Arthur D. Little nke Boston, chepụtara ngwaahịa cellulosic ọzọ, acetate, wee mepụta ya dị ka ihe nkiri. The mbụ azụmahịa textile eji maka acetate na eriri ụdị e mepụtara Celanese Company na 1924. Hermann Staudinger kpebisiri ike na polymer Ọdịdị nke cellulose na 1920. The compound bụ nke mbụ chemically synthesized (na-enweghị ihe ọ bụla biologically ewepụtara enzymes) na 1992, site na. Kobayashi na Shoda.

Ọdịdị nke cellulose

dezieCellulose bụ polymer mere nke na-emegharị molekul glucose na-ejikọta na njedebe na njedebe. Mkpụrụ ndụ cellulose nwere ike ịdị site na ọtụtụ narị ruo ihe karịrị 10,000 glucose nkeji ogologo. Cellulose dị n'ụdị nke carbohydrates dị mgbagwoju anya dị ka starch na glycogen. A na-emekwa polysaccharides ndị a site na ọtụtụ akụkụ nke glucose. Ihe dị iche n'etiti cellulose na ụmụ irighiri carbohydrate ndị ọzọ dị mgbagwoju anya bụ ka e si ejikọta ọnụ ọgụgụ glucose ọnụ. Na mgbakwunye, cellulose bụ polymer yinye kwụ ọtọ, na cellulose molecule ọ bụla dị ogologo ma dị ka mkpanaka. Nke a dị iche na starch, nke bụ molekul agbakọtara. Nsonaazụ nke ọdịiche ndị a na nhazi bụ na, ma e jiri ya tụnyere starch na carbohydrates ndị ọzọ, cellulose enweghị ike ịkụda ya n'ime glucose ya site na enzymes ọ bụla nke ụmụ anụmanụ na-emepụta..

Ụdị

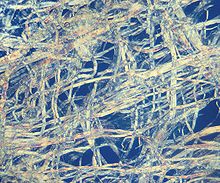

dezieAkara cellulose sitere n'okike

dezieA ka na-amata eriri cellulose sitere n'okike dị ka akụkụ nke osisi mbụ n'ihi na a na-edozi ha dịka ọ dị mkpa iji sachaa eriri maka iji mee ihe. [citation needed] Dịka ọmụmaatụ, eriri owuwe ihe ubi dị ka bọl owuwe ihe ọṅụṅụ dị nro nke ha si na ya. Akpụkpọ anụ linin yiri eriri siri ike nke osisi flax. Fiber niile "okike" na-agafe usoro ebe a na-ekewapụ ha na akụkụ nke osisi ahụ nke a na-ejighị eme ihe maka ngwaahịa ikpeazụ, na-emekarị site na owuwe ihe ubi, ịsacha, wdg. Ọnụnọ nke agbụ nke ọtụtụ puku mkpụrụ ndụ glucose jikọtara ọnụ na-enye ohere nnukwu njikọ hydrogen n'etiti ìgwè OH na agbụ ndị dị n'akụkụ, na-eme ka ha na-etinye n'ime eriri cellulose. N'ihi ya, cellulose na-egosipụta obere mmekọrịta na mmiri ma ọ bụ ihe ọ bụla ọzọ na-agwọ mmiri. Dị ka ihe atụ, ogho na osisi anaghị agbaze kpamkpam na mmiri ma nwee ike ịrụ ọrụ. Ebe ọ bụ na cellulose enweghị usoro helix dị ka amylose, ọ naghị ejikọta na iodine iji mepụta ngwaahịa na-acha.

Fiber cellulose a rụrụ

dezieFiber cellulose a na-emepụta na-esite na osisi ndị a na-edozi n'ime anụ ma mechaa wepụ ya n'otu ụzọ ahụ a na-eme eriri aka dị ka polyester ma ọ bụ naịlọn. Rayon ma ọ bụ viscose bụ otu n'ime eriri cellulose "mepụtara", a pụkwara iji osisi mee ya.

Ọdịdị na ihe onwunwe

dezieAkwara okike nwere microfibrils nke cellulose na matrix nke hemicellulose na lignin. Ụdị ọdịdị a na kemịkalụ ha na-ahụ maka njirimara igwe nke enwere ike ịhụ. N'ihi na eriri ndị sitere n'okike na-ejikọta hydrogen n'etiti ogologo agbụ, ha nwere nkwụsi ike na ike dị mkpa.

Ihe ndị mejupụtara ya

dezieIhe ndị bụ isi nke eriri okike (lignocelluloses) bụ cellulose, hemicellulose, lignin, pectin na ash. Pasentị nke ihe ọ bụla dịgasị iche maka ụdị eriri ọ bụla dị iche iche, Otú ọ dị, n'ozuzu, bụ ihe dị ka 60-80% cellulose, 5-20% lignin, na 20% nke mmiri, ma e wezụga hemicellulose na obere pasent nke ihe ndị fọdụrụnụ. Njirimara nke eriri na-agbanwe dabere na ọnụọgụ nke ihe ọ bụla, ebe ọ bụ na hemicellulose na-ahụ maka ịmịkọrọ mmiri, mmebi nke bio- na okpomọkụ ebe lignin na-ahụ na nkwụsi ike nke okpomọkụ mana ọ bụ ihe kpatara mmebi UV. A na-egosi ihe ndị mejupụtara eriri ndị a na-ahụkarị n'okpuru ebe a; [1] ndị a dịgasị iche dabere ma eriri ahụ bụ eriri bast (nke a na-enweta site na mkpo), eriri osisi (nke a nwetara site na osisi), ma ọ bụ eriri akwụkwọ (nke a hụrụ site na akwụkwọ).

| Ụdị eriri | Cellulose (%) | Lignin (%) | Hemicellulose (%) | Pectin (%) | Ash (%) | |

|---|---|---|---|---|---|---|

| Akpụkpọ anụ | Fiber flax | 71 | 2.2 | 18.6 – 20.6 | 2.3 | - |

| Mkpụrụ flax | 43–47 | 21–23 | 24–26 | - | 5 | |

| Kenaf | 31–57 | 15–19 | 21.5–23 | - | 2–5 | |

| Jute | 45–71.5 | 12–26 | 13.6–21 | 0.2 | 0.5–2 | |

| Hemp | 57–77 | 3.7–13 | 14–22.4 | 0.9 | 0.8 | |

| Ramie | 68.6–91 | 0.6–0.7 | 5–16.7 | 1.9 | - | |

| Akpụkpọ anụ | Kenaf | 37–49 | 15–21 | 18–24 | - | 2–4 |

| Jute | 41–48 | 21–24 | 18–22 | - | 0.8 | |

| Akpụkpọ akwụkwọ | Abaca | 56–63 | 7–9 | 15–17 | - | 3 |

| Sisal | 47–78 | 7–11 | 10–24 | 10 | 0.6–1 | |

| Henequen | 77.6 | 13.1 | 4–8 | - | - | |

Ihe onwunwe

dezieNzaghachi nke eriri cellulose na nrụgide igwe na-agbanwe dabere na ụdị eriri na ọdịdị kemịkal dị. A na-egosi ozi gbasara njirimara igwe dị na chaatị dị n'okpuru ma nwee ike iji ya tụnyere njirimara nke eriri ndị a na-ejikarị eme ihe dị ka eriri iko, eriri aramid, na eriri carbon.

| Fiber | Mkpụrụ (g/cm3) | Ịdị ogologo (%) | Ike nke ịdị nro (MPa) | Modulu Young (GPa) |

|---|---|---|---|---|

| Ogwe aka | 1.5–1.6 | 3.0–10.0 | 287–597 | 5.5–12.6 |

| Jute | 1.3–1.46 | 1.5–1.8 | 393–800 | 10–30 |

| Akpụkpọ anụ | 1.4–1.5 | 1.2–3.2 | 345–1500 | 27.6–80 |

| Hemp | 1.48 | 1.6 | 550–900 | 70 |

| Ramie | 1.5 | 2.0–3.8 | 220–938 | 44–128 |

| Sisal | 1.33–1.5 | 2.0–14 | 400–700 | 9.0–38.0 |

| Obi ọjọọ | 1.2 | 15.0–30.0 | 175–220 | 4.0–6.0 |

| Softwood kraft | 1.5 | - | 1000 | 40.0 |

| Igwe E | 2.5 | 2.5–3.0 | 2000–3500 | 70.0 |

| Igwe S | 2.5 | 2.8 | 4570 | 86.0 |

| Aramid | 1.4 | 3.3–3.7 | 3000–3150 | 63.0–67.0 |

| Carbon | 1.4 | 1.4–1.8 | 4000 | 230.0–240.0 |

Ihe onwunwe elu naihu ihu

dezieHydrophilicity, roughness na ụgwọ elu na-ekpebi mmekọrịta nke eriri cellulose na gburugburu mmiri. Ka ọ dị na 1950, a na-enyocha ụgwọ dị na interface dị n'etiti ogho dị ka eriri cellulose kachasị na gburugburu mmiri site na usoro nwere ike ịgba mmiri iji nyochaa ikike zeta elu.[2] N'ihi oke ọzịza nke eriri lignocellulosic, a hụla njikọ dị n'etiti ikike zeta na ikike mmiri.[3] Ọbụna maka iji eriri mkpofu dị ka ihe nkwalite na ihe ndị mejupụtara, ejirila ihe ngwọta nyocha mmiri nyochaa eriri ndị buru ibu.[4] A na-achọta nyocha banyere njirimara electrokinetic nke eriri okike gụnyere cellulose na eriri lignocellulosic na Handbook of Natural Fibers .

Ngwa

dezieIhe ndị e ji mee ihe

dezie| Matrix | Fiber |

|---|---|

| Epoxy | Abaca, achara, jute |

| Rubber sitere n'okike | Ịgba ọkụ, sisal |

| Nitrine rubber | Jute |

| Phenol-formaldehyde | Jute |

| Polyethylene | Kenaf, pineapple, sisal, eriri osisi |

| Polypropylene | Flax, jute, kenaf, sunhemp, ọka wit, eriri osisi |

| Polystyrene | Osisi |

| Polyurethane | Osisi |

| Polyvinyl chloride | Osisi |

| Polyester | Banana, jute, pineapple, sunhemp |

| Styrene-butadiene | Jute |

| Rubber | Mmanụ nkwụ |

Ihe ndị mejupụtara bụ ụdị ihe ndị a na-emekarị site na njikọta nke eriri na ihe na-ejikọta (matrix). Njikọ a na-agwakọta njirimara nke eriri na matrik iji mepụta ihe ọhụrụ nke nwere ike ịdị ike karịa eriri naanị. Mgbe ejikọtara ya na polymer, a na-eji eriri cellulose eme ihe iji mepụta ụfọdụ ihe ndị siri ike dịka Biocomposites na plastik siri ike. Tebụl ahụ na-egosipụta polymer matrices dị iche iche na eriri cellulose ha na-agwakọta mgbe niile.[5]

Ebe ọ bụ na njirimara macroscopic nke eriri na-emetụta omume nke ihe mejupụtara, ihe ndị a na-esonụ na-adọrọ mmasị:

- Dimensions: Mmekọrịta dị n'etiti ogologo na dayameta nke eriri bụ ihe na-ekpebi na nnyefe nke mgbalị na matrix. Tụkwasị na nke a, akụkụ na-adịghị mma na ọdịdị fibrillated nke eriri osisi na-enyere aka ijikọta ha n'ime matrix na-emebi emebi.

- Ọnụ ọgụgụ oghere na ịmịkọrọ mmiri: Fiber nwere oghere dị ukwuu na nnukwu oghere dị n'ime. N'ihi ya, mgbe a na-etinye eriri n'ime ihe na-ejikọta ya, ha na-amị nnukwu matrix. Mmetụta dị elu nwere ike ịkpata mkpụmkpụ fiber na ọzịza matrix. Otú ọ dị, oke oghere na-enye aka na mbelata ịdị arọ, mmụba ụda olu, na obere okpomọkụ nke ihe ikpeazụ.

- Ike nke ike: yiri, na nkezi, na eriri polypropylene. [<span title="This doesn't make sense in this setting. Why does tensile strength affect the resulting composite? Isn't tensile strength a result of how the matrix and fiber binds? (January 2019)">clarification needed</span>]

- Elastic modulus: Fiber cellulosic nwere obere modulus nke elasticity. Nke a na-ekpebi ojiji ya n'ịrụ ihe ndị na-arụ ọrụ na ọkwa na-agbawa agbawa, yana nnukwu ike na-amịkọrọ ma na-eguzogide ike dị ike. [<span title="Again, how does this apply the macroscopic characteristics of the fiber? This seems to be about the resulting material. (January 2019)">clarification needed</span>]

Akwa akwa

dezieN'ime ụlọ ọrụ akwa, a na-eji cellulose eme ihe dị ka eriri dịka rayon, (gụnyere modal, na Lyocell mepụtara n'oge na-adịbeghị anya). A na-emepụta eriri cellulose site na ịgbasa anụ ahụ.[6] Fiber ndị dabeere na cellulose nwere ụdị abụọ, nke e mere ka ọ dị ọhụrụ ma ọ bụ cellulose dị ọcha dịka site na usoro cupro-ammonium na cellulase gbanwere dịka cellulose acetates.

Fiber aka mbụ, nke a na-akwalite dị ka silk aka, ghọrọ nke a maara dị ka viscose n'ihe dị ka 1894, ma mesịa bụrụ rayon na 1924. A chọpụtara ngwaahịa yiri nke a a maara dị ka cellulose acetate na 1865. Rayon na acetate bụ eriri aka, mana ọ bụghị nke aka mere n'ụzọ zuru oke, na-abụ ngwaahịa nke Ihe oriri a na-agbari nke nwere osisi sitere n'okike. Ha abụghịkwa ihe owuwu aka nke silk, nke bụ polymer nke protein anụmanụ. Ọ bụ ezie na a chọpụtara eriri aka ndị a n'etiti narị afọ nke iri na itoolu, mmepụta nke oge a na-aga nke ọma malitere mgbe e mesịrị.

Nchịkọta

dezieNgwa enyemaka nke eriri cellulose / nzacha nwere ike inye ihe nchebe iji nyochaa ihe dị ka cellulose ntụ ntụ, ma e wezụga ịkwalite mmeziwanye na nghọta. [citation needed] Dị ka ntụ na-enweghị ntụ na nke na-abụghị abrasive nzacha, mee ka nhicha ghara ime mgbalị mgbe usoro nzacha na-enweghị mmebi na mgbapụta ma ọ bụ valvụ. Ha na-enyocha ihe ndị na-adịghị ọcha nke ígwè ma na-amị ihe ruru 100% nke mmanụ emulsified na ihe na-esi ísì ụtọ. N'ozuzu, eriri cellulose na ngwa nzacha nwere ike imeziwanye arụmọrụ nzacha mgbe ejiri ya dị ka isi ma ọ bụ ọgwụgwọ precoat n'ụzọ ndị a:

- Okporo ụzọ dị na septum nzacha na obere mgbapụta na gaskets na oche akwụkwọ

- Imeziwanye nkwụsi ike nke achịcha enyemaka nzacha iji mee ka ọ na-eguzogide nrụgide na nkwụsịtụ

- Ịmepụta uwe elu yiri nke ahụ na-enweghị oghere maka ebe nzacha dị irè karị

- Imeziwanye ntọhapụ nke achịcha na ibelata ihe ndị dị mkpa maka ihicha

- Igbochi obere ihe na-agba ọbara

- Ịkwado ngwa ngwa na ngwa ngwa ma belata mmetọ a na-agbari agbari

Ntụnyere ya na eriri ndị ọzọ

dezieN'iji ya tụnyere eriri ndị e mepụtara, eriri cellulose nwere uru dị mkpa dị ka obere, ọnụ ala, ha nwere ike imegharị, ma nwee ike imebi.[7] N'ihi uru ya, enwere ike iji eriri cellulose mee ihe dị ka ihe na-anọchi anya eriri iko na ihe ndị mejupụtara.

Nsogbu gburugburu ebe obibi

dezieIhe a na-ere ahịa mgbe niile dị ka "fiber bamboo" bụ n'ezie ọ bụghị eriri ndị na-eto n'ụdị ha sitere na osisi bamboo, kama ọ bụ anụ bamboo a na-edozi nke ọma nke a na-ewepụta dị ka eriri.[6] Ọ bụ ezie na usoro a adịghị mma maka gburugburu ebe obibi dị ka "fiber bamboo" na-apụta, ịkụ na owuwe ihe ubi bamboo maka fiber nwere ike, n'ọnọdụ ụfọdụ, bụrụ ihe na-adịgide adịgide na gburugburu ebe obibi karịa owuwe ihe ọkụkụ na-eto ngwa ngwa ma kpochapụ ebe obibi ọhịa dị ugbu a maka osisi.

Hụkwa

dezie- Mgbanwe eriri

Ebem si dee

dezie- ↑ Xue (2007). "Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review". Journal of Polymers and the Environment 15 (1): 25–33. DOI:10.1007/s10924-006-0042-3.

- ↑ Mason (1950-06-01). "Electrokinetic Properties of Cellulose Fibers: Ii. Zeta-Potential Measurements by the Stream-Compression Method" (in en). Canadian Journal of Research 28b (6): 323–338. DOI:10.1139/cjr50b-040. ISSN 1923-4287.

- ↑ Bismarck (2002). "Surface characterization of flax, hemp and cellulose fibers; Surface properties and the water uptake behavior" (in en). Polymer Composites 23 (5): 872–894. DOI:10.1002/pc.10485. ISSN 0272-8397.

- ↑ Pothan (2002-01-01). "Influence of chemical treatments on the electrokinetic properties of cellulose fibres". Journal of Adhesion Science and Technology 16 (2): 157–178. DOI:10.1163/156856102317293687. ISSN 0169-4243.

- ↑ Saheb (1999). "Natural fiber polymer composites: A review". Advances in Polymer Technology 18 (4): 351–363. DOI:<351::AID-ADV6>3.0.CO;2-X 10.1002/(SICI)1098-2329(199924)18:4<351::AID-ADV6>3.0.CO;2-X.

- ↑ Jump up to: 6.0 6.1 Fletcher (2008). Sustainable fashion and textiles design journeys. London: Earthscan. ISBN 9781849772778. OCLC 186246363. Kpọpụta njehie: Invalid

<ref>tag; name ":0" defined multiple times with different content - ↑ Mohanty (2000). "Biofibres, biodegradable polymers and biocomposites: An overview". Macromolecular Materials and Engineering 276-277 (1): 1–24. DOI:<1::AID-MAME1>3.0.CO;2-W 10.1002/(SICI)1439-2054(20000301)276:1<1::AID-MAME1>3.0.CO;2-W.